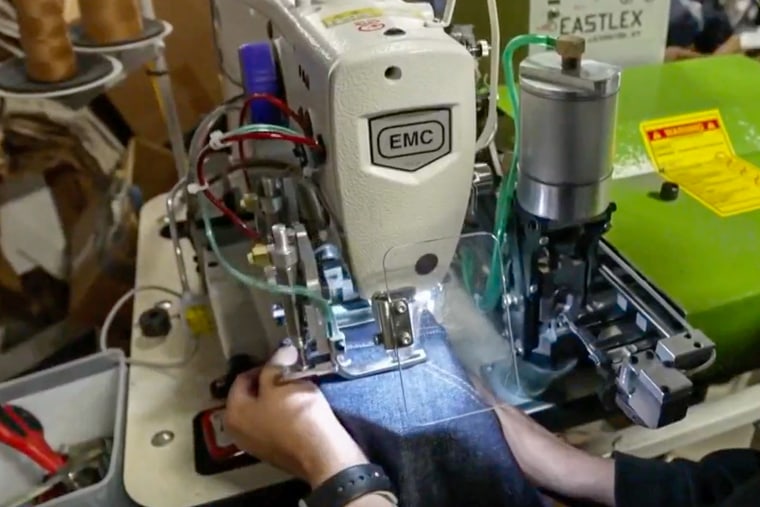

In the quiet town of Shawnee, Oklahoma, the rapid whir of sewing machines fills one of the last surviving American garment factories. Inside, denim from 100% American cotton is cut and sewn by hand into jeans, with a “Made in USA” tag stitched into every pair.

Founded in 1903, Round House Jeans is Oklahoma’s oldest manufacturer. Vice President David Antosh, whose family has run the company for over six decades, describes making affordable American-made jeans as both his family’s heritage and a way to support his community.

“Our No. 1 goal here at Round House Jeans is to make affordable American-made jeans that the average American can buy,” explained Antosh, who prices his denim pants at just $70 a pair and says he pays his employees above-market wages. It’s a vision that comes at a high cost and low return.

“Our profit margins are extremely low,” Antosh admitted about his American factory. “We make hardly any money on these jeans.”

The company embodies a lot of President Donald Trump’s “America first” economic ethos, but it’s also an example of how hard it’ll be for the president to compel clothing manufacturers to move operations to the United States. Despite higher tariffs intended to reshore manufacturing, scarce and costly skilled labor, limited domestic materials, and outdated technology have made manufacturing overseas both cheaper and more efficient.

Round House makes clothes in America with domestic cotton and paying above-market wages, but Antosh acknowledged it’s only possible because he also sells jeans sewn in Bangladesh at far higher margins. He said the higher profits from those imported jeans subsidize the price of his American-made products and pay for his Shawnee factory.

A pair of American-made jeans that Round House sells for $70 carries a 5% margin or less, meaning they cost above $66 to produce. By comparison, apparel retailers typically aim for at least 30% margin on products, according to Anna Livermore, CEO of V. Mora, a fashion consulting firm. Many target margins well above that, she said.

Antosh said his biggest challenge is building his sewing workforce. With so few U.S. apparel companies still operating, experienced workers are hard to find. He trains every new hire from scratch, which is a process that can take months or years before they’re fully productive. “It’s a very highly skilled job that requires a lot of patience, a lot of learning,” he said.

Despite the above-market pay attracting plenty of applicants, about three-quarters of new hires quit within the first few months, unable to handle the demands of the job.

By contrast, his Bangladesh-sewn jeans, which are still made with 100% American cotton, sell for $40 a pair, nearly half the price of the U.S.-made version, but deliver far higher margins of 20%.

Round House has been hesitant to raise prices on its American-made jeans, both out of principle and fear of the consequences. “Every time we have a price increase, we hear from customers who say I’d love to buy American-made but can no longer afford it,” Antosh said. He has seen competitors go out of business after price hikes drove customers away. According to a Conference Board survey released Monday, the appeal of “Made in USA” has faded since 2022, as many Americans now link it to higher costs amid higher price sensitivity.

Among the top goals for Trump and his administration in hitting trading partners with steep tariffs is bringing manufacturing capacity back to the U.S., even if it comes at the price of short-term market and economic duress. But Antosh said tariffs won’t help his company.

“It’s a hardship for us,” Antosh said. “When jeans sewn outside the U.S. become more expensive from tariffs, we can’t subsidize our American-made jeans as much and their price must go up, meaning fewer customers can afford Made-in-USA.”

Clothing imports already faced tariffs of 12%-17% before Trump’s presidency, according to the United States Fashion Industry Association. An additional 20% reciprocal tariff on Bangladeshi products, which became effective Aug. 7, would chip away at Round House’s profits. But even with the added tariffs, producing jeans in Bangladesh still costs far less than in the U.S. Antosh maintained that even with a hypothetical 100% tariff, Bangladeshi production would still come out cheaper than making the same jeans in Oklahoma.

Only 2.5% of clothing sold in America is produced domestically, according to AllAmerican.org, a U.S. manufacturing advocacy group. The rest is imported from places like China, Vietnam, India and Bangladesh, where labor is much cheaper. In the 1990s, U.S. apparel factories employed almost a million people. Today, that number has dropped below 100,000.

The U.S. lacks the capacity, materials and technology to meet fashion companies’ sourcing needs, said Sheng Lu, a professor of fashion and apparel studies at the University of Delaware. He also sees no clear evidence that tariff policies have driven fashion companies to source more domestically. In his 2025 Fashion Industry Benchmarking Study, over 80% of apparel companies said they plan to diversify sourcing to offset tariffs, while just 17% expect to increase sourcing from the U.S.

Another challenge for U.S. apparel manufacturing is its inability to produce a wide range of goods, said Joseph Ng, CEO of Shift Fashion Group, a consultancy that works with manufacturers. Aside from a handful of luxury brands, most U.S.-made apparel is limited to basic items like T-shirts, hoodies and socks, due to the fact that American factories “don’t have the skill set, machinery or materials to make anything beyond that,” Ng explained.

Ng pointed to Louis Vuitton’s Texas factory as an example of how brands attempting more complex products face steep challenges. Opened in 2019 during Trump’s first presidency, the luxury brand’s facility produces designer handbags but has a defect rate far higher than the industry norm, making it the company’s worst-performing facility, according to a report from Reuters.

To stay in business, Round House keeps things simple. “We don’t chase the latest fashion,” Antosh said. “We’re always about making things very similar to how we always have, even 100 years ago.” Chasing fast-changing fashion trends, he said, would require frequent retraining, making U.S. production inefficient and unsustainable.

Round House’s slim U.S. margins leave little room for error, Ng said.

“If he only had that business, he’d be one mess-up away from going out of business,” Ng cautioned, noting that garment manufacturing has multiple potential points of failure. A single mistake, such as misplacing rivets on a batch of jeans, could wipe out what little profit there is.

But Antosh said the goal has never been about maximizing profits. His focus is on preserving his family company’s heritage, keeping American manufacturing alive and sustaining his community with good jobs. As a testament to his commitment to his employees, many of his workers have stuck around for decades.

“There’s very few factories like ours that still exist,” Antosh said. “I don’t know if anyone else could be making affordable American-made jeans, like we do. That’s our reason for existence. If we weren’t here, offering it at this price point, who would be?”